How Does a Wood Pellet Mill Reduce Carbon Emissions and Support Sustainable Energy?

2025-11-25

How Does a Wood Pellet Mill Reduce Carbon Emissions and Support Sustainable Energy?

Wood Pellet Mills contribute significantly to global carbon reduction goals. Biomass pellets are considered carbon-neutral because the CO₂ released during combustion is offset by natural absorption during plant growth.

Additionally, Wood Pellet Mills reduce open burning of agricultural and forestry waste, a major source of particulate pollution. Instead, this biomass is converted into clean-burning, high-efficiency pellets.

Pellet production also reduces reliance on coal and fossil fuels. Many countries now co-fire wood pellets with coal to lower emissions in power plants.

FAQ

Q: Are wood pellets environmentally friendly?

A: Yes, they are renewable, carbon-neutral, and produce low emissions.

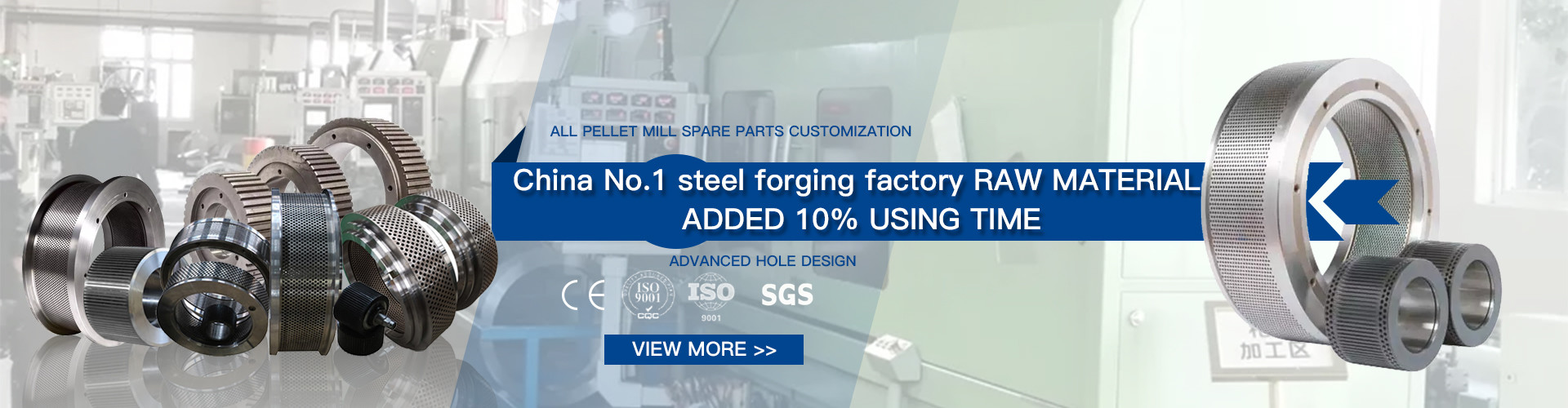

APEX BIOMASS is established in 2015 in Liyang ,Jiangsu Province ,which is a pioneer enterprise engaged in complete biomass /waste /feed pellet production line design /manufacture engineering ,pellet mill spare parts customization etc. Apex Biomass Equipment advantage is that owning experienced R&D team ,strict scientific management combined with we opening wood pellet factory experience and advanced processing equipment ,now we can manufacture high-class ,qualified machinery equipment . Because of factory direct supply ,advanced deign and quick after sales service ,customer orientation we has earned many customer at domestic and foreign good reputation , we sincerely do things and help customer solves problems ,we look forward your long terms business cooperation .

View More

What Are the Key Differences Between Flat Die and Ring Die Wood Pellet Mills?

2025-11-25

What Are the Key Differences Between Flat Die and Ring Die Wood Pellet Mills?

Flat die and ring die Wood Pellet Mills are the two main types used in the biomass pellet industry. They differ significantly in structure, capacity, and application.

Flat die mills have a simple design, making them suitable for small-scale production and home use. They are cost-effective and easy to maintain. However, their output capacity is lower, and pellet uniformity may vary.

Ring die mills, on the other hand, are designed for continuous, high-capacity industrial operations. They use a rotating ring die and multiple rollers to produce dense, consistent pellets. Ring die machines offer higher efficiency, lower energy consumption per ton, and longer service life.

We Apex Ring die advantage that can gurantee two year ,including main shaft , hollow shaft , all gear in the reducer box no broken :

Welcome you to contact us , APEX BIOMASS IS THE MANUFACTURER AND ONE -STOP SERVICE PROVIDER WITH 15 YEARS EXPERIENCE .

Contact :

Mori Lu

WA/LINE /WECHAT :+86 - 18562307530

View More

How to Choose the Right Wood Pellet Mill: A Complete Buying Guide for Smart Investors

2025-11-25

How to Choose the Right Wood Pellet Mill: A Complete Buying Guide for Smart Investors

Are you considering investing in a wood pellet mill for biomass fuel production? Choosing the right pelletizing equipment is essential to ensure high-quality output, long-term durability, and a solid return on investment. Whether you're a seasoned producer or new to biomass, this guide will walk you through the key steps to selecting a reliable pellet mill—and how our expert team can help you every step of the way.

Step 1: Define Your Needs – The Foundation of Every Smart Purchase

Before contacting a supplier, it's crucial to clarify your production goals and raw material characteristics. This information determines the type of equipment you need and ensures you get accurate quotes and solutions.

✅ Raw Material Characteristics

Type: Are you using single-origin sawdust, a mix of shavings and wood scraps, or agricultural straw?

Moisture Content: Ideal moisture content for pelletizing is between 12% and 18%. Incorrect moisture levels reduce yield and pellet quality.

Particle Size: After grinding, materials should typically be under 5mm.

Wood Type: Hardwoods (e.g., oak) and softwoods (e.g., pine) wear on dies and rollers differently due to fiber structure.

✅ Production Capacity

How many tons per hour do you need to produce? Common capacities include 0.5 ton/hour, 1 ton/hour, and 2 tons/hour. This directly affects the machine model and motor power you should choose.

✅ Pellet Specifications

What pellet diameter do you require? The most common sizes are 6mm and 8mm, which will determine the die specifications.

✅ Power Source

Does your facility use three-phase electricity, or do you need a diesel-powered machine? Clarifying this early helps avoid costly mistakes.

Step 2: Focus on Equipment Quality – What Makes a Good Pellet Mill?

When buying a wood pellet mill, core component quality directly affects long-term performance and maintenance costs. Here's what to look for:

View More

Which Industries Benefit the Most from Using Wood Pellet Mills?

2025-11-25

Which Industries Benefit the Most from Using Wood Pellet Mills?

Wood Pellet Mills serve a wide range of industries seeking sustainable and cost-effective energy solutions. The most prominent sectors include:

Biomass Power Plants

Power generation facilities rely heavily on wood pellets for consistent energy output. Pellets offer high calorific value and low ash production.

Heating Systems

Residential and commercial heating systems increasingly use wood pellets as an eco-friendly alternative to gas and coal.

Agriculture

Farmers use pelletized biomass for heating, livestock bedding, and waste management.

Wood Processing Plants

Factories producing furniture, plywood, or flooring often integrate Wood Pellet Mills to recycle wood waste and reduce disposal costs.

Export Fuel Industries

Wood pellets are one of the most traded biomass fuels globally, with strong demand in Europe and Japan.

FAQ

Q: Are wood pellets used in households?

A: Yes, pellet stoves are widely used for home heating.

APEX BIOMASS is established in 2015 in Liyang ,Jiangsu Province ,which is a pioneer enterprise engaged in complete biomass /waste /feed pellet production line design /manufacture engineering ,pellet mill spare parts customization etc. Apex Biomass Equipment advantage is that owning experienced R&D team ,strict scientific management combined with we opening wood pellet factory experience and advanced processing equipment ,now we can manufacture high-class ,qualified machinery equipment . Because of factory direct supply ,advanced deign and quick after sales service ,customer orientation we has earned many customer at domestic and foreign good reputation , we sincerely do things and help customer solves problems ,we look forward your long terms business cooperation .

Welcome you to contact us freely , Experiencd company provide high level wood pellet line .

View More

What Factors Determine the Output Quality of a Wood Pellet Mill?

2025-11-25

What Factors Determine the Output Quality of a Wood Pellet Mill?

The output quality of a Wood Pellet Mill depends on several key variables, all of which influence pellet durability, density, and combustion performance.

The first and most important factor is raw material moisture content. Materials that are too wet or too dry cannot bond correctly during pelletizing. Optimal moisture is typically 10–15%. Consistent moisture ensures smooth production and high pellet density.

The second factor is material size. Raw biomass must be finely crushed, usually to less than 5 mm. Proper crushing helps ensure uniform compaction when passing through the die.

Die design also plays a major role. Different die compression ratios and hole diameters produce different pellet densities. Choosing the right die for specific biomass types—such as hardwood, softwood, or agricultural waste—is essential.

Other factors include temperature control, roller pressure, and machine stability. Efficient cooling systems and well-maintained rollers help achieve smooth, shiny pellets without cracks.

FAQ

Q: Why do pellets sometimes crumble?

A: This is often caused by low compression ratio, incorrect moisture, or poor raw material quality.

View More